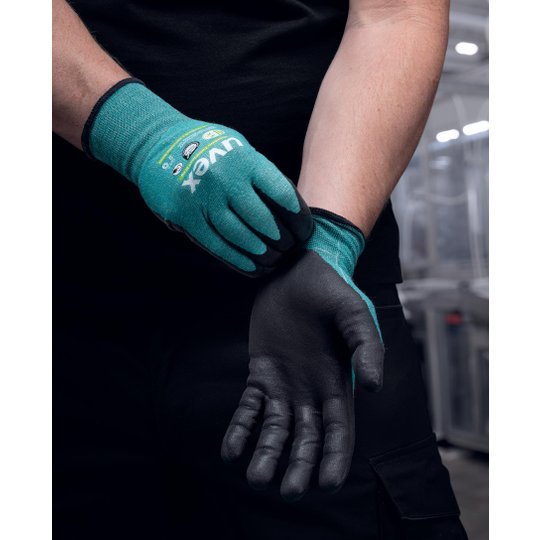

uvex Bamboo TwinFlex® D XG

Noticeably superior. Bamboo TwinFlex® D XG: Sustainability, comfort and sensitivity combined with high cut protection (Cut D)

Patented Bamboo TwinFlex® technology provides a silky feel on the skin and ensures high and fast moisture absorption, delivering long-lasting comfort and high wearer acceptance. Thanks to its adaptive fit, the glove conforms to each individual hand shape within 3–5 minutes of wear. High-performance fibres offer a high level of protection against abrasion and cuts. The uvex protexxion zone offers twice the abrasion resistance (200%) compared to the palm of the glove, thereby increasing the glove's durability. Thanks to the Xtra-Grip coating, the Bamboo TwinFlex® D XG offers excellent grip in dry and slightly damp/oily conditions. In addition, the glove is made from 45% sustainable materials: recycled polyamide and bamboo viscose, which is derived from renewable raw materials.

- Excellent sensitivity in cut protection level D

- High level of wearer comfort thanks to bamboo fibre

- 45% sustainable materials: recycled polyamide and bamboo viscose, which is based on renewable raw materials

- High efficiency due to long service life, all thanks to uvex protexxion + premium Xtra-Grip coating

- Made in Germany, free from solvents

- Patented Bamboo TwinFlex® yarn technology

- Silky soft feel against the skin

- Fast absorption and high retention of moisture

- Adaptive fit: Adapts precisely to fit the shape of any hand within 3 to 5 minutes of wearing

- Dermatologically tested for skin compatibility, free from allergenic accelerators

- Particularly light, thin and flexible with high cut protection (level D )

- No need to remove the glove thanks to touchscreen capability

- Uvex protexxion zone with smooth material surface ensures trouble-free workflow

- In accordance with EN 407, the model is suitable for contact warmth up to +100 °C

- Installation of sharp-edged or unburred parts

- Glass and metalworking industry

- Automotive industry

- Precision work

- Quality control

- Paper and packaging industry

- Areas with use of touchscreens

- Food processing

- Carbon footprint: 0.47 kg CO₂ eq

- Carbon footprint of production: 0.15 kg CO₂ eq

- Carbon footprint of material: 0.29 kg CO₂ eq

- Carbon footprint of transportation: 0.02 kg CO₂ eq

- Carbon footprint of packaging: 0.01 kg CO₂ eq

- CO₂ - calculation period: 04/2024

- Legal notice regarding carbon footprint: Calculation method: IPCC 2021 GWP 100a (based on ISO 14067) SimaPro 9.5.0.0 ecoinvent database 3.9. Scope: cradle-to-customer. These CO₂ values are valid at the time of calculation and may be subject to change. For more information, visit uvex-safety.de/co2-fussabdruck

| Attribute | Value |

|---|---|

| Product category | Safety gloves |

| Product type | Cut protection gloves |

| Product family | uvex bamboo Twinflex |

| Type | With knitted cuff, With reinforced thumb crotch |

| Colour | Green |

| Gender | Unisex |

| Coating | XtraGrip-NBR |

| Product protection | Safety gloves for handling and processing food |

| Certificates | proDerm, STANDARD 100 by OEKO-TEX®, Suitable for food handling |

| Reuse | Reusable (R) |

| uvex technology | Bamboo TwinFlex® technology, Touchscreen capability |

| Product line | protecting planet |

| Sizes | 6 |

| Allergy information | Free from allergenic accelerators |

| Coating surface area | Fingers, Palm |

| Suitability for industrial working environments | Suitable for dry and slightly damp work environments |

| Health protection | Free of harmful solvents (DMF, TEA) |

| Size linked | 6 |

| Outer material | Elastane, Bamboo viscose, Recycled Polyamide (PA), High-performance polyethylene (HPPE), Steel |

| Mechanical risk protection | Protects against grazes, Protects against cutting injuries, Protects against lacerations |

| Heat risk protection | Protects against contact heat |

| uvex quality seal | Made in Germany |

| Standard | EN ISO 21420:2020/EN 388:2016 + A1:2018/EN 407:2020 |

| Product name | uvex |

CE Declaration of Conformity

Noticeably superior. Bamboo TwinFlex® D XG: Sustainability, comfort and sensitivity combined with high cut protection (Cut D)

Patented Bamboo TwinFlex® technology provides a silky feel on the skin and ensures high and fast moisture absorption, delivering long-lasting comfort and high wearer acceptance. Thanks to its adaptive fit, the glove conforms to each individual hand shape within 3–5 minutes of wear. High-performance fibres offer a high level of protection against abrasion and cuts. The uvex protexxion zone offers twice the abrasion resistance (200%) compared to the palm of the glove, thereby increasing the glove's durability. Thanks to the Xtra-Grip coating, the Bamboo TwinFlex® D XG offers excellent grip in dry and slightly damp/oily conditions. In addition, the glove is made from 45% sustainable materials: recycled polyamide and bamboo viscose, which is derived from renewable raw materials.

- Excellent sensitivity in cut protection level D

- High level of wearer comfort thanks to bamboo fibre

- 45% sustainable materials: recycled polyamide and bamboo viscose, which is based on renewable raw materials

- High efficiency due to long service life, all thanks to uvex protexxion + premium Xtra-Grip coating

- Made in Germany, free from solvents

- Patented Bamboo TwinFlex® yarn technology

- Silky soft feel against the skin

- Fast absorption and high retention of moisture

- Adaptive fit: Adapts precisely to fit the shape of any hand within 3 to 5 minutes of wearing

- Dermatologically tested for skin compatibility, free from allergenic accelerators

- Particularly light, thin and flexible with high cut protection (level D )

- No need to remove the glove thanks to touchscreen capability

- Uvex protexxion zone with smooth material surface ensures trouble-free workflow

- In accordance with EN 407, the model is suitable for contact warmth up to +100 °C

- Installation of sharp-edged or unburred parts

- Glass and metalworking industry

- Automotive industry

- Precision work

- Quality control

- Paper and packaging industry

- Areas with use of touchscreens

- Food processing

- Carbon footprint: 0.47 kg CO₂ eq

- Carbon footprint of production: 0.15 kg CO₂ eq

- Carbon footprint of material: 0.29 kg CO₂ eq

- Carbon footprint of transportation: 0.02 kg CO₂ eq

- Carbon footprint of packaging: 0.01 kg CO₂ eq

- CO₂ - calculation period: 04/2024

- Legal notice regarding carbon footprint: Calculation method: IPCC 2021 GWP 100a (based on ISO 14067) SimaPro 9.5.0.0 ecoinvent database 3.9. Scope: cradle-to-customer. These CO₂ values are valid at the time of calculation and may be subject to change. For more information, visit uvex-safety.de/co2-fussabdruck

| Attribute | Value |

|---|---|

| Product category | Safety gloves |

| Product type | Cut protection gloves |

| Product family | uvex bamboo Twinflex |

| Type | With knitted cuff, With reinforced thumb crotch |

| Colour | Green |

| Gender | Unisex |

| Coating | XtraGrip-NBR |

| Product protection | Safety gloves for handling and processing food |

| Certificates | proDerm, STANDARD 100 by OEKO-TEX®, Suitable for food handling |

| Reuse | Reusable (R) |

| uvex technology | Bamboo TwinFlex® technology, Touchscreen capability |

| Product line | protecting planet |

| Sizes | 6 |

| Allergy information | Free from allergenic accelerators |

| Coating surface area | Fingers, Palm |

| Suitability for industrial working environments | Suitable for dry and slightly damp work environments |

| Health protection | Free of harmful solvents (DMF, TEA) |

| Size linked | 6 |

| Outer material | Elastane, Bamboo viscose, Recycled Polyamide (PA), High-performance polyethylene (HPPE), Steel |

| Mechanical risk protection | Protects against grazes, Protects against cutting injuries, Protects against lacerations |

| Heat risk protection | Protects against contact heat |

| uvex quality seal | Made in Germany |

| Standard | EN ISO 21420:2020/EN 388:2016 + A1:2018/EN 407:2020 |

| Product name | uvex |